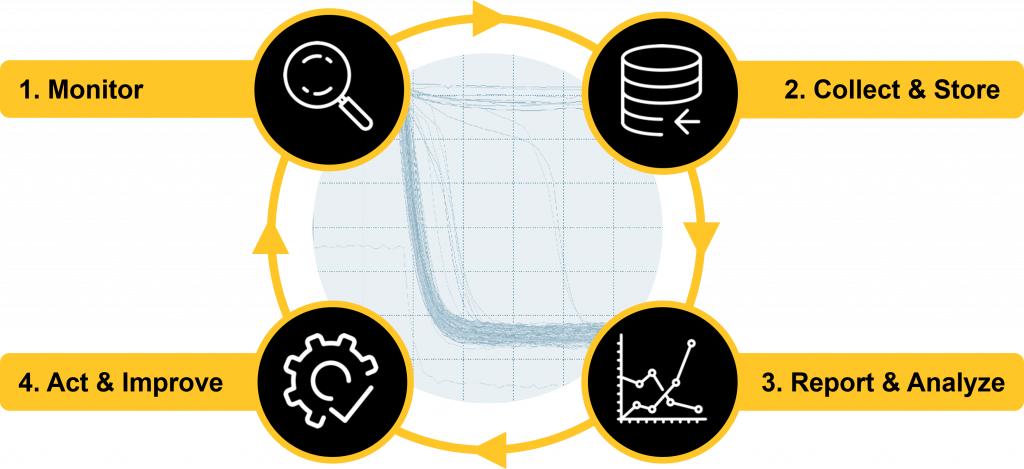

Sciemetric’s data collection and manufacturing analytics solution delivers everything manufacturers need to access the benefits of Industry 4.0. This solution addresses the four critical elements required for a smart, connected factory: Collect and Store, Analyze and Report, Act, Improve.

Sciemetric’s QualityWorX data collection and management solution enables data collection from any critical-to-quality process across your line and makes data accessible in one centralized database. This data can then be accessed for in-depth analysis and reporting using Sciemetric Studio, a visualized data analytics software tool that allows you to identify and solve problems in real-time, and enable continued improvement on your line.

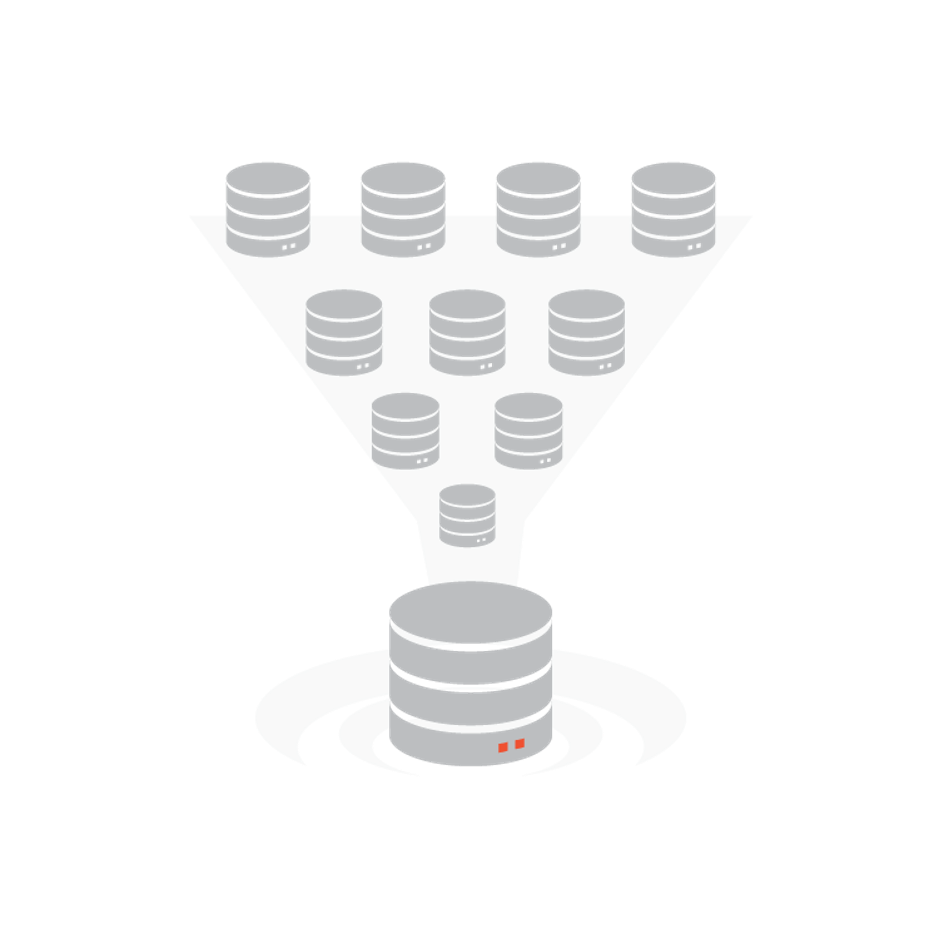

QualityWorX Manufacturing Data Collection

- Eliminate data silos for better access to data

- Simplify and optimize management of your plant’s data

- Standardize organization of data for quicker access when you need it

- Build a cohesive history for manufactured parts across assembly processes

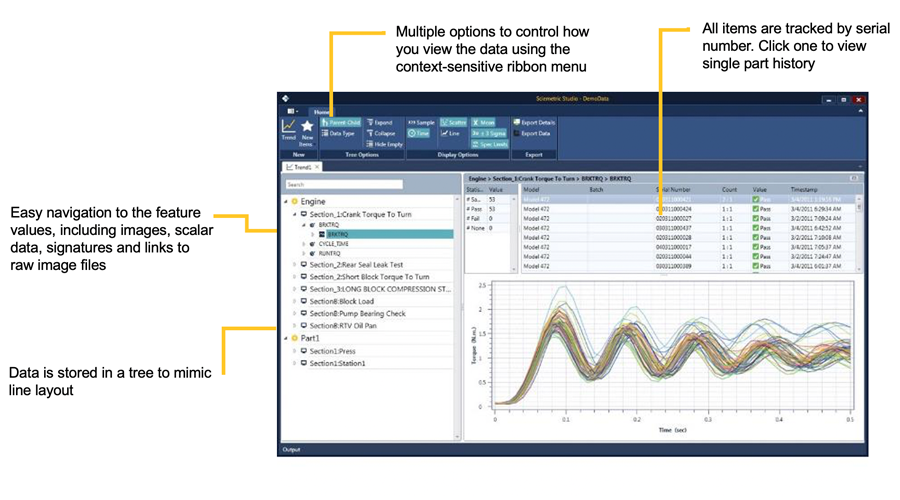

Sciemetric Studio Manufacturing Data Analytics

Sciemetric Studio enables quick, in-depth analysis of data from across your production line. It makes it easy to produce reports that help you analyze manufacturing and product quality trends and find deviations in your process before they result in failed parts and affect downstream production. With these data-driven insights, you will be resolving issues within hours—not days or weeks—and proactively managing your factory.

Sciemetric Studio enables the quickest path from analysis to answers, allowing you to:

- Set real-time alerts for processing deviations using SPC, etc.

- Visualize and compare all types of data from the production line

- Overlay thousands of waveforms for meaningful analysis

- Identify trends and easily pinpoint anomalies that could lead to failed parts

- View the complete data history for a part, across multiple stations (by serial number)

- Re-process and analyze historical data offline to optimize test limits, etc.

- Compare and trend information across stations to determine variations

- And more

Let us show you how this can help you manage your test stations, request a demonstration.

Make better, quicker decisions on your production line with data insights

- Quickly identify root cause of quality issues

- Access actionable insights to resolve issues faster

- Access data-driven limit-setting to speed up test setup and optimization

- Perform offline ‘what if’ analysis to optimize tests without affecting live production

- Improve first time yield / first time through (FTY / FTT)

- Enable full part traceability (birth history record) by serial number

- Access proof of compliance by serial number

- Increase efficiency and continuously improve your manufacturing processes

Consult the experts in manufacturing data collection and analytics

Sciemetric is an expert in manufacturing data analytics, having worked with manufacturers across the globe for over 40 years, helping them use their process data to improve product quality and efficiency.

Our local team at Sciemetric India has the knowledge and expertise to help you identify how best to use data on your line and how to make the most of your analytics and insights. If you have questions about data collection and analytics on your production line, we’re here to help!