Sciemetric’s sigPOD is an in-station in-process testing and process monitoring platform that provides accurate and reliable defect detection during assembly. The perfect manufacturing 4.0 solution, the sigPOD utilizes fast, advanced digital process signature analysis measurement to provide unparalleled quality management.

Monitor nearly any process to identify defects as they occur and improve product quality

The sigPOD can be applied to nearly any process on your production line, including

Crimp

Dispense

Press-force / press-fit

Leak testing

Noise and vibration and harshness testing (NVH)

Welding

Functional testing

Laser profile inspections

Torque testing

+ More!

The sigPOD’s flexible, easily configurable design makes it easy to scale and apply to critical-to-quality stations across the line. Standardizing testing technology with a common test and monitoring solution across the plant, using the same hardware and user interface across multiple tests, simplifies training, maintenance and test management to achieve greater efficiency and reduce costs.

Key features of the sigPOD

The sigPOD is built to deliver accurate quality monitoring on parts during assembly to identify defective assemblies in real-time, when they are the easiest and most cost-effective to address. Key features that power the sigPOD include:

- Unique PSV™ technology provides best-in-class defect detection and identification

- PSV™ software can be easily configured for any application, driven entirely by user-selectable fields–no programming required!

- Standard application templates support a wide range of common manufacturing processes

- Intuitive point-and-click configuration makes the sigPOD easy to setup and operate

- Compact, robust design easily integrates into any manufacturing station

- Offers versatile methods of gathering meaningful process and quality data from connected machines across the smart factory

- Use comprehensive SPC tools to signal process deviations in real time, and access a variety of SPC reports, including trending, histograms, statistics

- Store up to 2,000 records on the sigPOD

- Stand-alone or networked operation options enables local or remote desktop monitoring of quality data

- Easy communication with PLCs for integrated monitoring and control

- Many communication options, including PROFINET, EtherNet/IP, Modbus TCP

Access the most accurate manufacturing defect detection with sigPOD’s process signature verification (PSV)

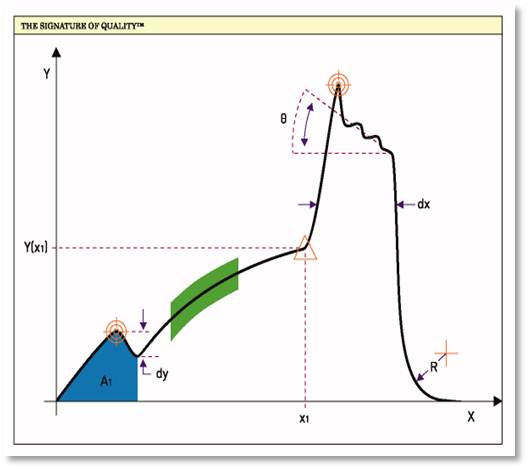

The sigPOD offers the most accurate defect detection technology on the market using digital process signatures, which powers our PSV software. Most in-process test or monitoring systems rely on only a few points of measurement to identify a pass/fail, but the sigPOD uses applies complex algorithms to analyze hundreds or thousands of points of data to catch even subtle deviations that identify product defects.

Overlay, analyze, visualize these signatures (or waveforms) in large populations to view trends at a station or focus your view down to a single serialized part. Use process signatures to identify the root cause of defects, access insights to improve test limits, adjust cycle times and more using precise data rather than guesswork.

SPC-enabled, visualized data reporting tools at the station

The sigPOD offers simple on-screen reports and visualized data to provide needed information right at the test station. Access histograms, overlay signatures from a group of texts and view other SPC information.

You also have the option to connect your sigPOD—or any data collection device—to Sciemetric’s QualityWorX and Sciemetric Studio, the industry’s most advanced manufacturing analytics tools. This brings all your data together in one place for deeper analysis. Use these tools to:

- Use SPC reports, including trending, histograms, statistics, to quickly signal process deviations and production quality problems

- Overlay data waveforms to quickly identify root cause of quality issues and resolve issues faster

- Improve first time yield / first time through (FTY / FTT)

- Enable full part traceability (birth history record) by serial number

- Perform an offline ‘what if’ analysis to optimize tests

- Improve production efficiency and continuously improve your manufacturing processes

Your local specialists in manufacturing defect detection

Sciemetric is a leader in in-process testing and process monitoring across the globe, working with the world’s top manufacturers to improve product quality and production efficiency through process monitoring, measurement, and data analysis. Sciemetric India is poised with local experts to provide the expertise and advice you need to apply the right systems for quality management in manufacturing; catch defects, improve your product quality, and boost production efficiency.