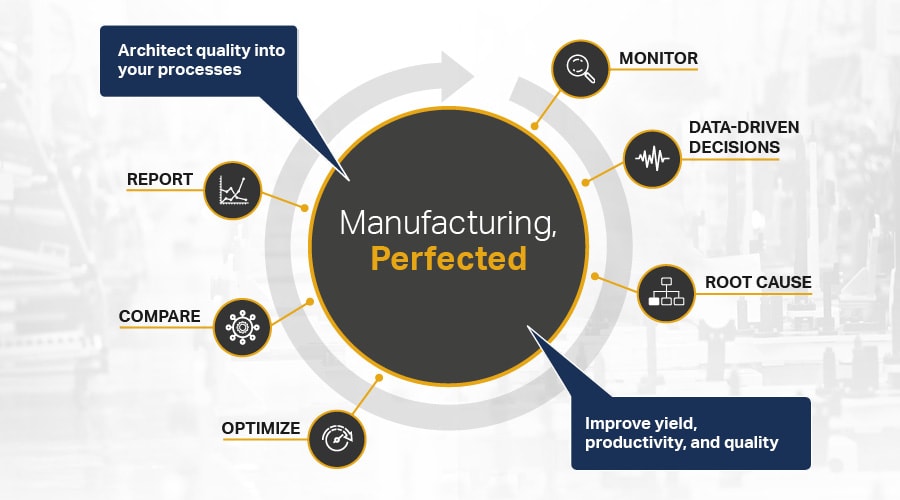

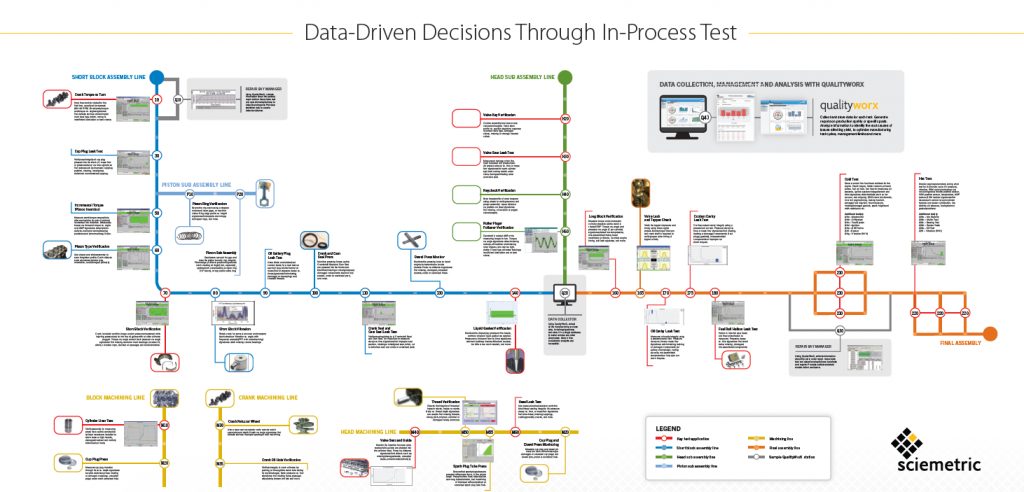

In-process testing (IPT), or in-process verification (IPV), is a proven methodology of critical-to-quality operations on a part as it is being manufactured. Using Sciemetric Industry 4.0 systems, you will catch product defects before they leave the production line, reducing costly scrap and wasted cycles.

Sciemetric’s in-process test and monitoring systems can be applied to nearly any test on your line, including crimp, dispense, press-force / press-fit, leak testing, noise and vibration and harshness testing (NVH), welding, functional testing, profile inspections, torque testing, and more. Our data management and industrial analytics software well help you realize use the data from your test stations to realize the benefits of Industry 4.0. Report on quality, quickly analyze and address issues, improve cycle time and productivity, and more.

Flexible, scalable solutions for in-process testing

sigPOD process monitoring system

Data collection and Industry 4.0 manufacturing analytics

FLEXIBLE SOLUTIONS FOR VIRTUALLY ANY PROCESS

Boost the intelligence of your entire line with sigPOD process monitoring equipment

sigPOD is one of Sciemetric’s out-of-the-box solutions for monitoring test and assembly processes that standardizes part test and process monitoring onto a single platform for manufacturers. Our in-station process monitoring tool uses advanced signature analysis to deliver real-time pass/fail feedback along with advanced defect detection. It has a compact, robust design and is expandable to accommodate up to an additional 16 analog channels or 64 encoder channels.

Improve virtually any industrial process with Manufacturing Analytics

Manufacturing Analytics is a universal industrial analytics platform to help you perfect almost any process in record time. This modular, distributed data analytics system removes barriers to collecting data, driving productivity improvements and cost savings. Whether your goals are improved product quality, greater process reliability, increased efficiency, or enhanced test repeatability, Sciemetric EDGE can help you achieve them.

Improving manufacturing process monitoring with digital process signature verification

Sciemetric EDGE is a universal industrial analytics platform that can help you perfect your processes in record time. This distributed data analytics system removes barriers to collecting and using data, for productivity improvements and cost savings.

Sciemetric EDGE is a universal industrial analytics platform that can help you perfect your processes in record time. This distributed data analytics system removes barriers to collecting and using data, for productivity improvements and cost savings.

Sciemetric EDGE is a universal industrial analytics platform that can help you perfect your processes in record time. This distributed data analytics system removes barriers to collecting and using data, for productivity improvements and cost savings.

One standard solution for automated defect recognition & analysis across your production line

Crimp:

Detects missing wires and terminals, crimp issues, incorrect wire gauge and other defects.

Dispense:

Provides accurate detection and visualization of bubbles, air voids, or partial hardening during the dispensing and application of sealants, coatings, and adhesives.

Noise and Vibration:

Production line testing for rotating machinery and motorized assemblies.

Force-Distance Monitoring:

Monitors every step of the press force operation to accurately and reliably catch incorrect orientation, improper insertion, cracks, and other defects as they occur.

Torque:

Multi-channel torque and encoder signal support for testing engine shafts, electric motors, and more.

Gauge and Profile:

Identify surface defects, detect incorrect assemblies, and monitor planarity in flat parts.

Weld:

Monitors voltage, current, force, distance, amplitude, frequency, and power in automotive assemblies, medical assemblies, and more.

Leak Tests:

Plug and play connectivity for leak testing engine chambers, medical devices, and other parts and components where seal integrity is critical.

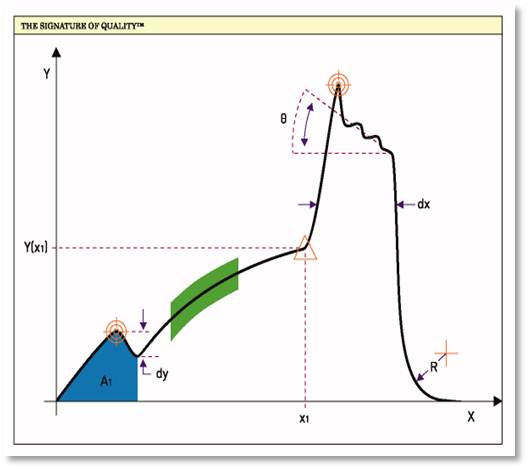

The most accurate manufacturing defect detection, powered by digital process signatures technology

The sigPOD uses unique digital process signature technology to deliver the most accurate defect detection on the market. Most in-process test or monitoring systems rely on only a few points of measurement to identify a pass/fail, but the sigPOD measures hundreds or thousands of datapoints for a more accurate recording of the process. Our tools then apply complex algorithms to analyze this data to catch even the smallest deviations that could lead to product defects.

Overlay, analyze, visualize digital process signatures (or waveforms) to view trends across stations or focused on a single part (identified by serial number). Our technology helps you identify the root cause of defects, access insights to improve test limits, adjust cycle times and moreusing precise data rather than guesswork.